3D printing of artificial vessels

Physiological (dimensionality, stiffness etc.) and biochemical (chemistry of the environment, growth factors) cues impact the behavior and morphology of cells. As a result, examining the response of cells cultivated under unidirectional laminar flow demands fabrication of surfaces with specific morphological, physical and chemical properties.

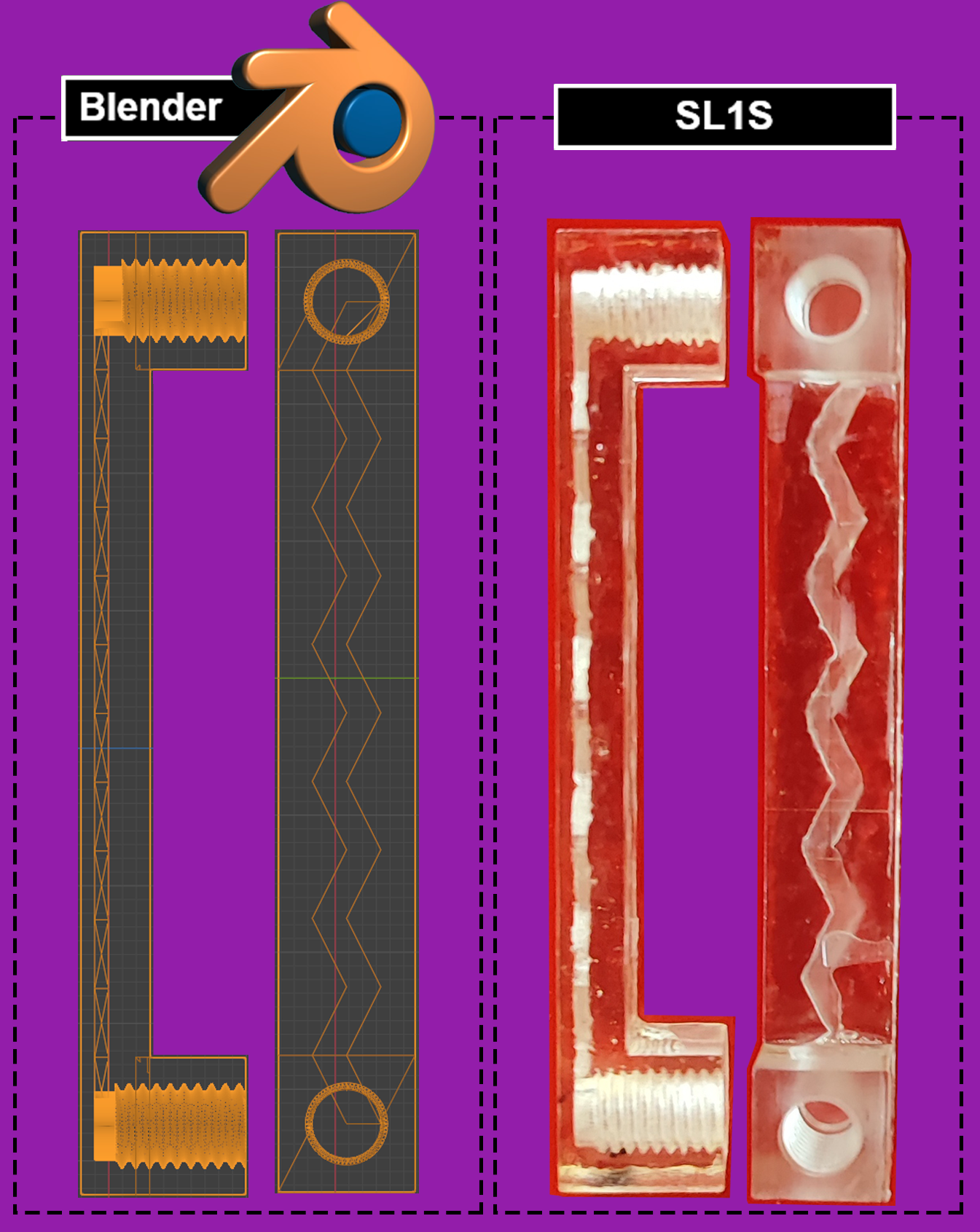

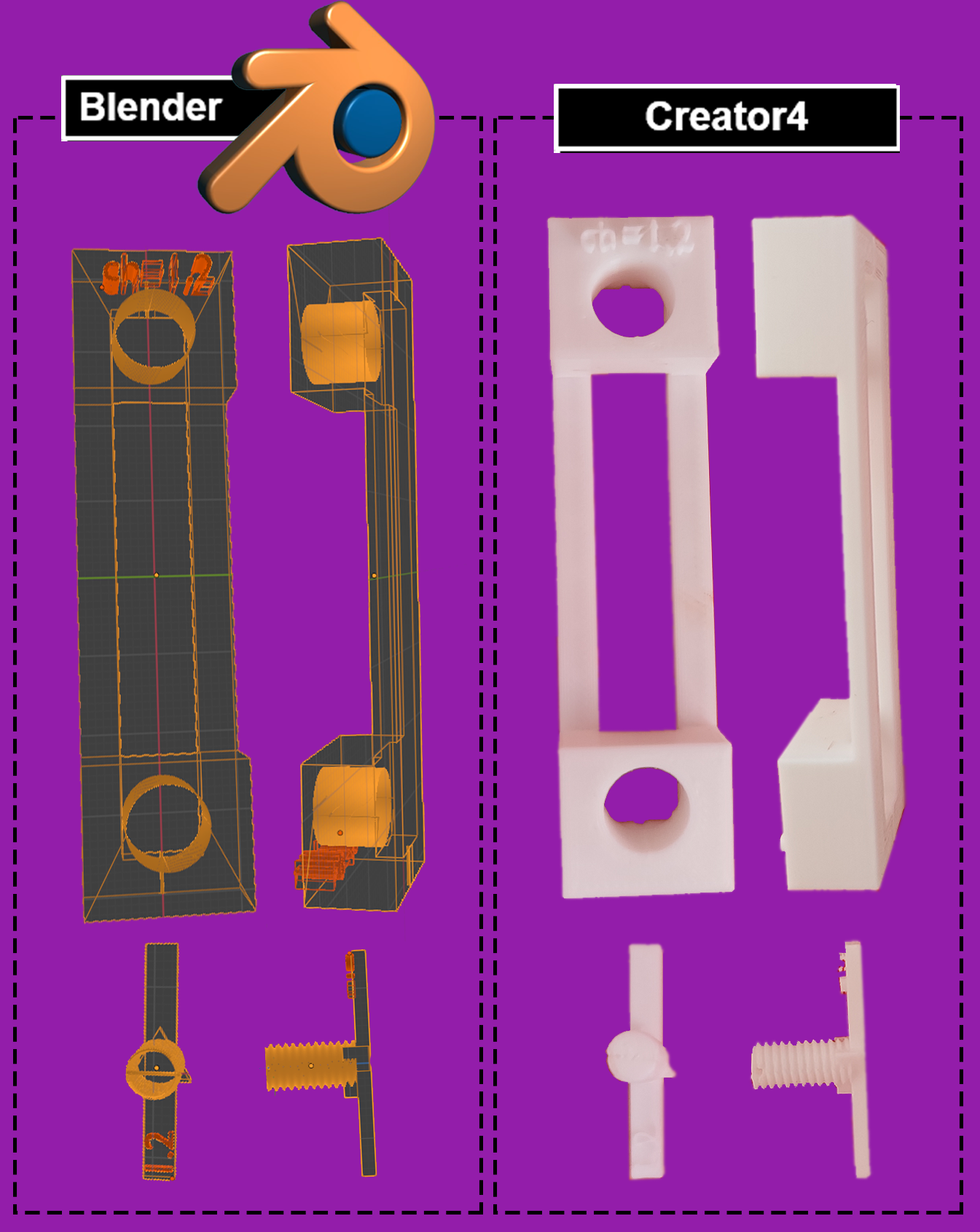

3D printing gives the capability to make surfaces with microstructures or microchannels. Actually, we can use 3D printers to construct desired surfaces directly using materials like resins or in the form of filaments. It is also possible to utilize surfaces from non-printable material, by creating a negative structure or a mold. The 3D printers used in our lab are Creator 4 by Flashforge and Prusa SL1S.

FDM 3D printer – Flashforge Creator 4

Overview

Creator 4 is an FDM(Fused Deposition Modeling) 3D printer. It heats/melts (hotend) polymers and pushes them (extruder) through a nozzle onto a platform, where the model is built. The material for printing is provided as filament spools of 1.75 mm in diameter. FDM printers extrude a thermoplastic filament in a series of layers over a build plate to create a three-dimensional object. Each extruder prints a point at a time. Consequently, printing time is proportional to the size of printed structure.

Creator 4 is also a CoreXY printer in terms of the way it prints. It has the latitudinal and longitudinal coordinates determined by two motors and timing belts on the Y-axis and X-axis. The Z-axis determines the print height, as the print surface will be lifted to meet the extruder.

The Creator 4's thermal-control system maintains the print chamber at 65℃, reducing model shrinkage, warping, and breakage. This ensures high print quality, precision, and a higher success rate.

Creator 4 can employ a wide variety of filament materials. Materials include Polycarbonates (PC), polyamide (PA (nylon)), Polypropylene (PP), polyethylene terephthalate glycol (PETG), Acrylonitrile styrene acrylate (ASA), acrylonitrile butadiene styrene (ABS), Polylactic Acid (PLA), (PC-ABS), Nylon Carbon Fiber (PACF), Polyethylene terephthalate and Carbon Fiber blend (PET-CF),(PP-CF), Polyamide and Glass Fiber blend (PA- GF),(PP-GF), Polyphenylene Sulfide and Carbon Fiber blend (PPS- CF), Thermoplastic Polyurethane (TPU 85A), Thermoplastic Elastomer (TPE), (TPB) and Thermoplastic Copolyester (TPC).

To print a structure, it must initially be modeled on a software such as Blender. The created STL file is inserted into FlashPrint 5 software slicing the 3D model. This is the file according to which the printer makes the structure. It’s important to insert appropriate supports, especially when there are extreme overhangs.

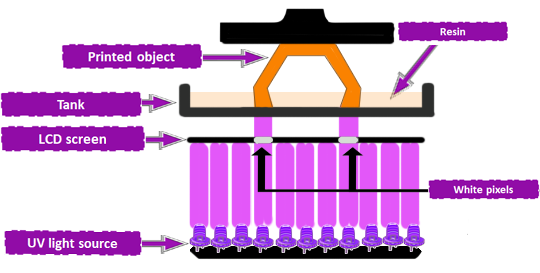

MSLA 3D printer – Prusa SL1S

Overview

SL1S is an MSLA (Masked Stereolithography) 3D printer. After filling the tank with the appropriate amount of resin, the printing process starts. Each layer's shape is displayed as a semi-transparent mask on an LCD screen, and the exposure is performed employing a high-performance UV LED. UV light can pass only through white pixels on the display. Owing to the fixed resolution of the LCD display, the printed objects have a fixed XY resolution. This method cures a whole layer at a time, meaning it doesn’t matter how many objects there are on the printing platform. So, printing time is proportional only to the number of layers, or in other words the height of the object.

After printing there are two important steps: washing and curing. CW1S is an accessorymade for this purpose. The printed object is washed with Isopropyl Alcohol (IPA) in order to rinse remnants and excess resin. After washing, UV curing of the object ensures polymerization of the whole object

To print a structure, it must initially be modeled on a software such as Blender. The created STL file is inserted into PrusaSlicer software slicing the 3D model. This is the file according to which the printer makes the structure. It’s important to insert appropriate supports, especially when there are extreme overhangs.